The state of the fabric/textile industry

Due to the COVID-19 situation, digitalization has infiltrated every aspect of the apparel business. Fabrics and textiles are among the most essential parts of the system, and digitalization is no exception.

However, the digitizing of fabrics/textiles has had a relatively slow uptake compared with other critical elements in fashion, such as patterns or human bodies. Why is this? Traditional methods require a lot of manual work and rely on seeing the actual products. Also, since fabrics/textiles are flat, it’s hard to imagine how they will look when molded into 3D. The final results of digital fabric presentation are beyond imagination, so most of the innovations in textiles and fabrics focus much more on reinventing the materials, constructions, and prints.

Innovation in textile and fabric

Considering innovations in textile or fabric, the first thing that comes to mind would be sustainable materials since fabric waste and pollution could be the most serious problem in the apparel business. With the uptick in environmental awareness, manufacturers put a lot of effort into studying how to make fabric’s production processes more sustainable or finding more natural materials for fabrics such as pineapple fiber, sustainable bamboo and others.

However, with the rise of textile/fabric technology, true to life visualization of 3D fabrics could lead to a tremendous change in the innovation of the textile and fabric industry.

Textile/ Fabric technologies and 3D scanning

3D scanning technology has exploded in popularity in 2020 due to COVID-19. Along with the travel ban and social distancing, people were prevented from going to trade shows and unable to attend physical meetings which lead to a big problem for an industry that depends highly on physical samples. Luckily innovative textile/fabric technologies could help. How do you start and what do you need to start?

The Physical Fabric

The 3D Digital Fabric Sample

4 steps to digitally transform your fabric/ textile business

Step 1: Create digital textiles/fabrics through the 3D fabric scanner

There are a lot of solutions for fabric scanning in the market. However, if you have a limited budget or you would like to test the water before investing a considerable amount of money, we recommend the Scanatic™ Nuno Fabric Scanner. This solution provides:

- Intelligent imagery processing engine that captures 3D texture display properties (color maps, specular maps, and UV maps) of fabrics in the smallest digital footprints.

- Intelligent color composition analysis

- Instant online 3D fabric preview

- Access to your own online digital fabric warehouse

Step 2: Build up your digital fabric warehouse

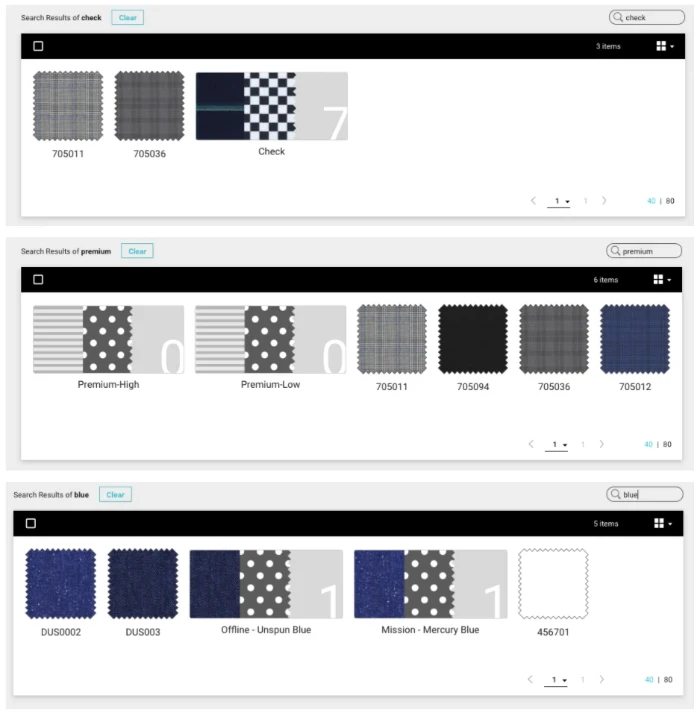

The idea of having a fabric warehouse of a considerable size is every brand’s dream. Far more environmentally friendly and cost effective, however, is to have a digital version. Our system will help you to systematize your fabric data so that sales and manufacturing staff can easily access them. Fabric data can be categorized based on texture, patterns, color, collections or other custom filters. However, if you already have your own digital fabric database, you may also connect our 3D fabrics with your internal IT systems or platforms for a better visualization.

Search fabrics by texture, patterns, color, collections or other custom filters

Step 3: Bring your fabric collection online and further implement 3D assets for a better customer experience

Other than 2D photos, you can provide an interactive 3D experience to your clients by applying 3D fabrics onto 3D garments. See a real example below:

Interactive 3D Experience

With the help of TG3D Studio’s Scanatic™ StyleBook Service, this interactive 3D experience is as easy as pie. The StyleBook Service is a 3D style management platform that connects seamlessly with the Scanatic™ Nuno Fabric Scanner, which means that you could easily apply the fabrics scanned by Scanatic™ Nuno Fabric Scanner to the 3D garments in the StyleBook Service. The end results can easily be shared to your clients via links or an embedded code on your website.

Embed interactive 3D experience on your website

The benefits to this are palpable. Your clients will have a more holistic visualization of how fabrics will present on a garment. This also means that you will be able to produce much more attractive marketing and sales materials faster and with more flexibility.

Step 4: Confirm required fabrics and send out the fabric swatches for feel and touch; Close the deal!

Interested in these steps and would like to learn more about how to start? Contact us now and our team will lead you throughout the transformation process!

Limitless possibilities in the future

3D digital fabrics are an excellent way of showcasing your stock in exhibitions. You can bring small fabric swatches for customers to feel & touch while displaying other fabrics on digital platforms such as your website or an iPad.

You can also create a digital showroom with VR/ AR applications. These are fun interactive experiences for the client. Learn more in our partner’s video: